Photos: 3-D printers

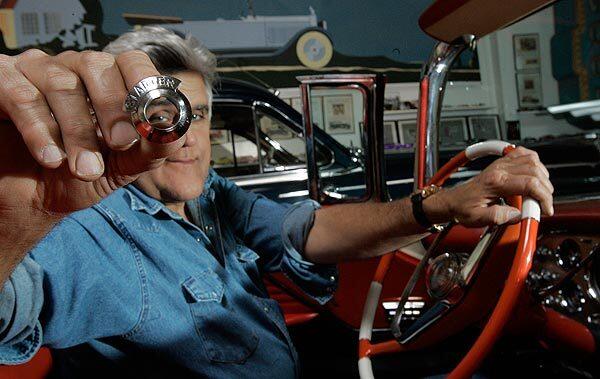

Jay Leno holds a starter switch bezel for the 1956 Packard Caribbean he keeps in his warehouse-sized Burbank garage, which houses his collection of more than 200 cars and motorcycles. A prototype for the hard-to-find auto part was designed and printed in plastic using a 3-D printer. (Gary Friedman / Los Angeles Times)

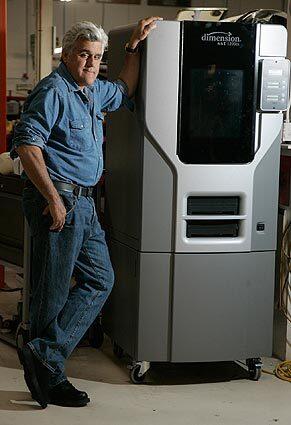

The industrial-quality Stratasys 3-D printer in Jay Leno’s garage is as big as a refrigerator and costs about $27,000. His mechanics design hard-to-find auto parts on a laptop computer and then use the machine to make them real. (Gary Friedman / Los Angeles Times)

Leno holds a water pump from a 1914 Premier. At right is a plastic prototype of the replacement water pump he is designing for the car. The prototype was made using the Stratasys 3-D printer Leno keeps in his Burbank garage. (Gary Friedman / Los Angeles Times)

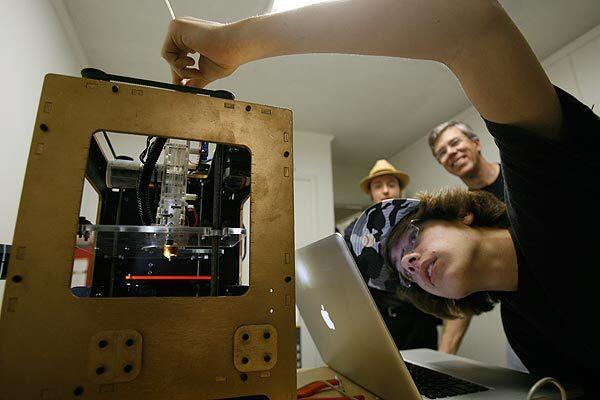

Brian Isdale, 14, and his father, Jerry Isdale, rear right, use a 3-D printer that Crash Space, a Culver City tech club, bought for its members. The $750 model, which comes in kit form, is the CupCake CNC by MakerBot. (Michael Robinson Chavez / Los Angeles Times)

Advertisement

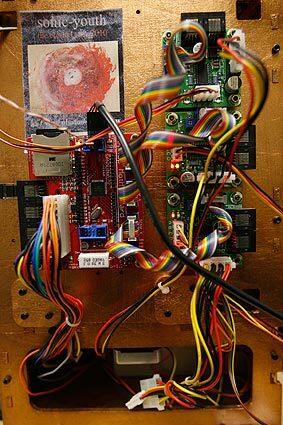

The CupCake CNC, which is primarily made of wood, is in the shape of a box with windows cut out so its working parts can be seen. Hovering over the top is an extruder that heats up ABS plastic and then moves in patterns directed by a computer. (Michael Robinson Chavez / Los Angeles Times)

Using their 3-D printer, Crash Space club members can envision an item, design it and then push a button to make it real. (Michael Robinson Chavez / Los Angeles Times)